In modern manufacturing, efficiency and automation are key factors in ensuring smooth and cost-effective production of goods. This is especially true in the food and beverage industry, which has a constant demand for high-quality products and efficient production processes. One of the areas where automation has had a significant impact is in the production of BIB filling machines.

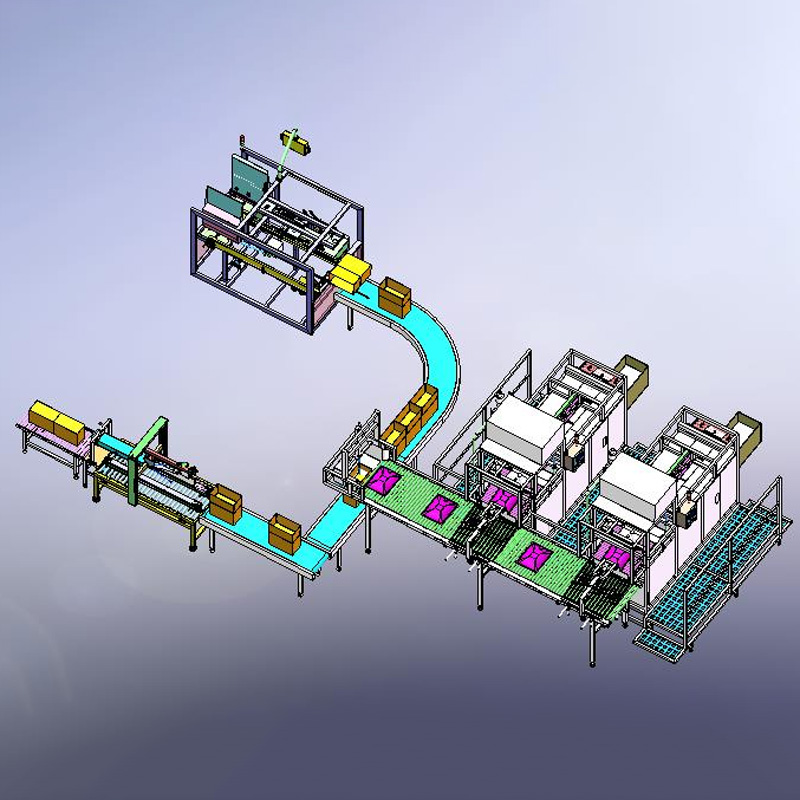

The BIB filling machine production line is an important part of the packaging and filling of beverages such as juice, wine and other liquid products. The entire process from filling to final packaging is automated, reducing manual intervention and costs while effectively reducing error rates and risks. This level of automation fundamentally changes the way BIB filling machines are produced, increasing efficiency and productivity. The BIB filling machine's production line consists of a series of interrelated processes that work seamlessly together to ensure efficient and accurate beverage filling and packaging.

The first step in the production line is filling liquid products into bags. This is where automation comes into play, as the filling process is precisely controlled to ensure accurate and consistent filling levels. This not only reduces the risk of product waste but also ensures that the final product meets the required quality standards.

Once the fill bags are sealed, they move along the production line to the next stage, which includes sealing and packaging the fill bags. Likewise, automation plays a vital role in this process as the machines are equipped with advanced sealing and packaging technology to ensure safe and hygienic sealing on the bags. This is critical to maintaining product integrity and freshness, especially for perishable beverages.

As filled and sealed bags move along the production line, they are automatically transferred to the final packaging stage, where they are placed in boxes for distribution and storage. The automated packaging process ensures bags are packed neatly and securely in boxes, ready for shipment to retailers or consumers. This level of automation not only speeds up the packaging process but also reduces the need for manual handling, thereby minimizing the risk of product contamination and damage.

One of the main advantages of a fully automatic BIB filling machine line is the significant reduction of manual labor and related costs. By streamlining production processes and minimizing the need for manual intervention, manufacturers can achieve higher levels of efficiency and productivity, ultimately saving costs and improving profitability. In addition, automation of the production line reduces the risk of human error, ensuring that the final product meets the required quality and safety standards. The automation of the BIB filling machine production line also enhances the overall safety of the production process. By minimizing the need to manually handle products, the risk of workplace accidents and injuries can be significantly reduced. Not only does this create a safer working environment for employees, it also helps manufacturers comply with strict safety regulations and standards.

Post time: May-24-2024